1. Energy Conservation Practices

The company had implemented, as one of the energy conservation programs, the replacement of all office daylight lamps with the T-5 model. This is an on-going program wherein by the time these old lamps (T-12 & T-8 models) get busted, it will be replaced by the T-5 model. This is also to minimize the capital expenditure incurred in replacing the entire lighting system of the company at one time.

Another practice is the synchronization of the start-up of all electric motors in the production department. This is to avoid the sudden surge of electric power consumption during the start of the electric motors. The practice is that, there will be an interval of 30 seconds before an electric motor can be put-on or start-up. That is, after start-up of one major electric motor, the next one will be started after 30 seconds, and so with the third and so on.

2. Reduction of Water Usage in the Production Process

Water consumption in the shell slicing and skinning process was largely reduce by the implementation of water valves in each of the slicing/skinning machine so that actual water consumption in this part of the production process.

Actual water usage on the different comfort rooms, wash areas and urinal areas were addressed. Complementing with these measures was the installation of a rain water reservoir tank, in which rain water collected use was integrated into the system. Thus, resulting to a reduced in water consumption by 68% as well as the green gas emission.

3. Waste Segregation and Recycling

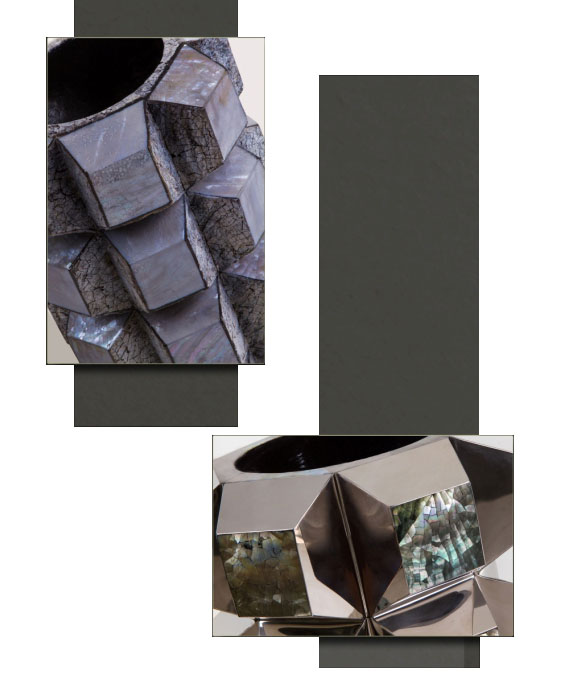

Powder waste from the grinding of shells and resin casings were collected and integrated into the production of new products developed using concrete. Our designers also developed new products utilizing the waste from cut shells and metallic cuttings. In the office, recycling of used papers had given us a substantial savings on office paper used.

4. Pollution Equipments and Waste Disposal

The company in continually improving machinery and equipment designs to give our workers ease and comfort in the respective work areas. Emphasis is given most especially in the reduction of dust emission and proper ventilation. Before waste are disposed of, it must be treated and be assured that it will not be harmful to the environment and to the immediate community.

5. Eco-Friendly and Indigenous Materials

One of the programs of the company is continuous research and development of products and designs using indigenous and eco-friendly materials. The fact that most of our raw materials used comes from nature, we take it as our responsibility to give back to nature. Thus the company is also endeavoured into the tree planting activity, wherein thousands of mahogany and white wood (pangantuhon) trees, hundreds of different fruit trees were planted in the mountain barangay of Toledo City.

6. Preventive Maintenance

Regular and consistent check-up, inspection and preventive maintenance activities of equipments is now a part of the company’s fundamental responsibility. This is to attain high efficiency and productivity in our production processes. Also, efficient use of equipments can minimize carbon footprint.